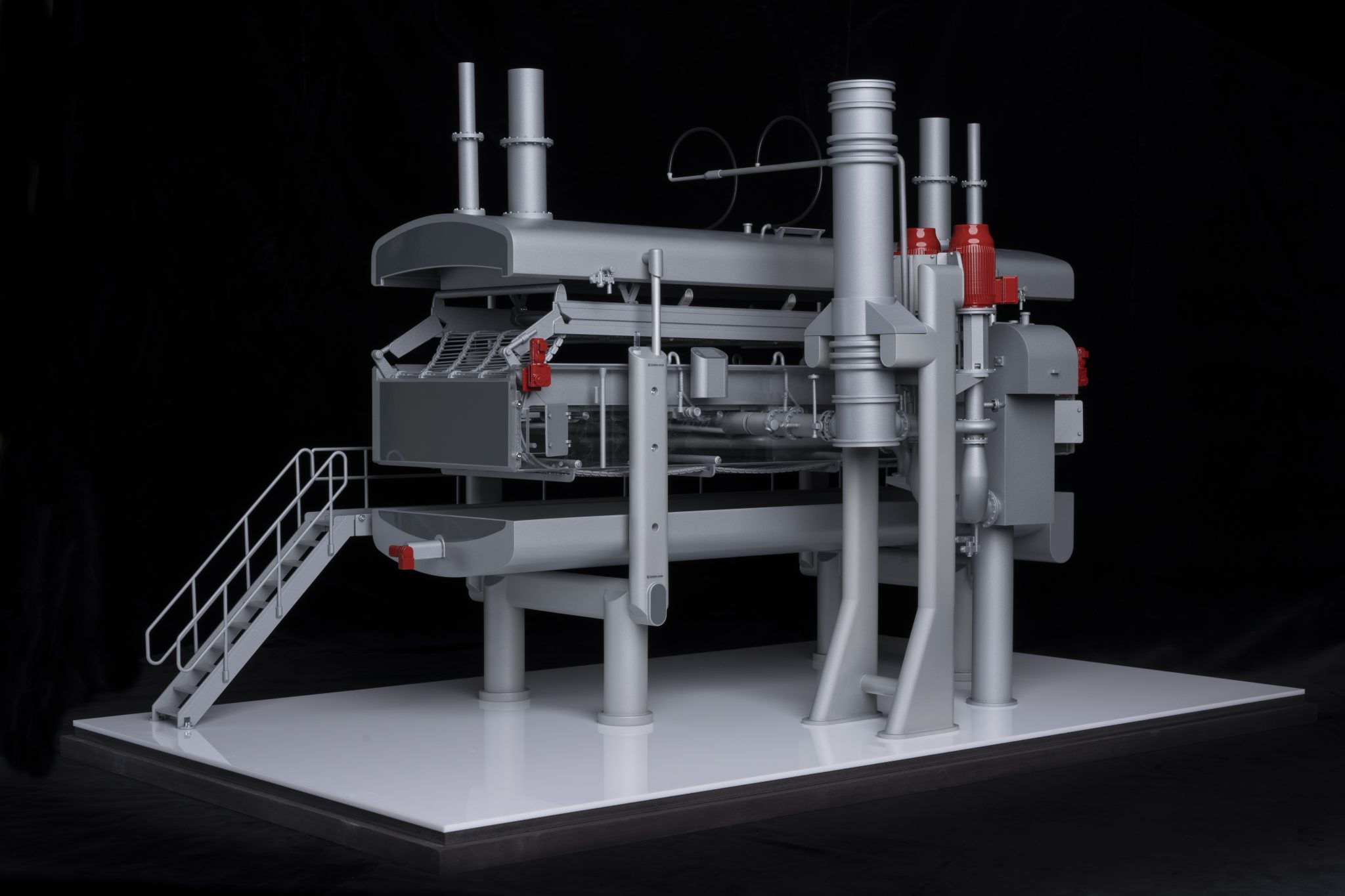

More and more clients are asking for a fair model to scale. This also applies to Ivo Sassen from design agency Groendijk Design. His customer wanted to present their latest device at a trade fair: a 12-meter fryer. A challenging project for SKM!

Project leader Ivo Sassen explains: ‘Our customers want to give their products their own identity. That’s why they reach out to us. In addition to making a good product, they look for a recognizable design that radiates quality. In order to properly show the external features that we draw, I regularly have 3D models made at SKM. The most special one? That’s definitely the model of the Kiremko CORDA Invicta. A 12-metre fryer with an unique oilcirculation system.’

Fits like Lego

Reducing the oven to a trade fair model was quite a challenge. ‘We provided a 1:1 CAD model to SKM. It had to be reduced to 1:16. But if you resize or scale something, you can’t print it right away. And if you divide a steel plate of 8 mm thick by 16, you are left with nothing. Fortunately, SKM has a lot of experience with this. They scaled the model to fit exactly like Lego.’

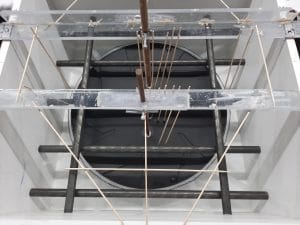

SLS, SLA and DLP

SKM used various printing techniques for this project. Many details have been adjusted and some parts have even been enlarged, because they were lost due to the resizing. In addition, the model had to be divided into parts to be able to create it using different printing techniques. For example, the circulation pump’s belt was made in one piece in SLS, while the larger parts were made in SLA. The small parts with a lot of detail are made with DLP. This allows you to fine print. In addition to printing, other techniques such as turning and milling were also used. The end result is perfectly painted and finished.

Professionals with an eye for detail

For Ivo this is one of the reasons to work with SKM. ‘At SKM, they have all techniques in house to carry out a complex project such as this one. When we ask them to make a model, we know: they get the job done. Employees have often been working at SKM for many years. They are passionate professionals with an eye for detail. That’s what you need for these kinds of projects. A company like SKM is becoming increasingly rare: with professionals who will brainstorm with you about possibilities and offer the highest quality. That is why we have been working with SKM for years!’